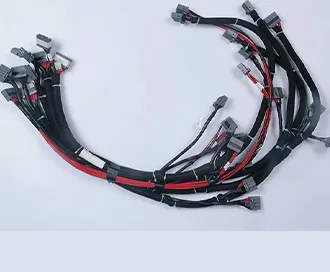

We have 17 years of rich experience in wire harness manufacturing and production. We have served more than 6,000 customers worldwide, who are distributed in the automotive,lighting, and new energy lighting, industries, With our professional knowledge of wire harnessmanufacturing,we can quickly bring your products to market.

VOCSON With more than 10 years of experience in wire and cable manufacturing services, VOCSON is ISO 9001:2015, ISO 14001:2015, UL and CE certified. Customers’ products comply with international quality control certifications starting from development, incoming material management and mass production. These products are also UL, CE and RoHS certified. We insist on rigorous and effective inspections in every ODM and OEM process. Our quality inspections are carried out in manufacturing management using customized precision instruments, specialized test procedures and functional test fixtures. Our quality philosophy: to achieve customer satisfaction, to fully meet customer needs, and to reduce costs to maintain competitive pricing.

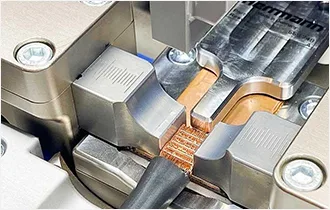

Programmable Cutter Stripper

Customer's

Requirements

Engineer

Analyze

Send Quote

Sampling

Sampling

Drawing

Construct

Mass

Production

QC

Packing

Delivery

Customer's

Requirements

Engineer

Analyze

Send Quote

Sampling

Drawing

Construct

Mass

Production

QC

Packing

Delivery

Wire & Cable Conductor Resistance Test

Insulation Resistance Test

Insertion And Extraction Force Testing

Terminal Section Cross Analysing

Pull Force Testing

Wiring checking

Salty spray Testing

Product AppearanceInspection

Swing Testing

Fast certification services: With 17 years of cable wire harness experience, Long-term cooperative testing laboratory can help get your certificates quickly.

1 Female to 2 Male Power Splitter Barrel Plug Cables

1 to 2 Way Under Cabinet Lights Cables

12V DC Power Security Camera Adapter Cables

18 Gauge Grey White Electrical Wire

18 Gauge insulated Tinned Copper Wire

18 Gauge LED Light Wire

20 Gauge DC Power Wires

20 Gauge Two Conductor wire

DC Female to 4 Male CCTv Camera Power Cables

Energy storage equipment wiring harness manufacturing

New energy wiring harness manufacturing

Medical equipment wiring harness manufacturing

VOCSON has different certifications for different standards. Certification proves how experienced and well-established the manufacturer is. When using wiring harnesses from us, safety can be guaranteed, and electrical hazards can be reduced to some extent.

There are several steps.

Step 1: Be clear of what wiring harness you want.

Step 2: Contact with us to discuss your requirements, including designs, usage, length, budget, etc. Talk the details as detailed as possible.

Step 3: We’ll will evaluate your requirements. Then start to make prototype and test.

Step 4: If it tests well, the production will be started.

Step 5: When all is done, we will deliver those harnesses.

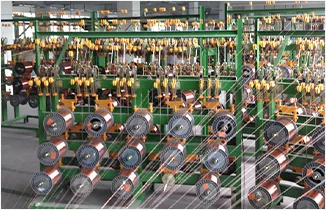

Automation makes the production of wiring harnesses more efficient and precise with high-quality. Here’s how:

As said before, cable harnesses can be used in a range of industries. So, they can be used for electric vehicles (EVs). To ensure safety and performance, We design cables that can handle high-voltage systems.

Wiring harnesses are crucial components in many industries and require the highest quality. Before it comes into the market, the manufacturer would conduct rigorous tests, including continuity testing, pull testing, as well as environmental testing. All those tests are aimed at controlling quality and ensure safety.

We values the following measures to ensure their product quality:

This makes sure that you can get high-quality products that meet your specifications to the most extent. Meanwhile, we have the knowledge and expertise to address issues, recommend the best materials, and ensure reliable performance. When there is something wrong, you can contact and get quick solutions.

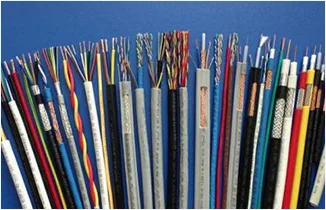

Depending on the application and industry, the materials vary as there are different requirements for durability, flexibility, and environmental resistance. Generally, you can refer to the following content:

Absolutely YES! By utilizing recyclable and biodegradable materials that adhere to environmental requirements, numerous wire harness manufacturers give consumers environmentally friendly solutions. At the same time, they take the following aspects into consideration:

To purchase environmentally friendly wire harnesses, you can search keywords on shopping websites, such as recycle cable harness, etc.

Cable harness companies invest in equipment to keep up with new developments in technology. To meet the needs of many industries, we blend innovative production techniques with aesthetically beautiful and useful designs.

Looking for Affordable Wiring Harnesses for Your Project?

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.