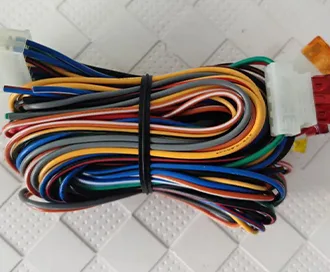

VOCSON delivers precise, high-quality, and efficient Cable - Wire Harness Assembly solutions tailored to your needs.

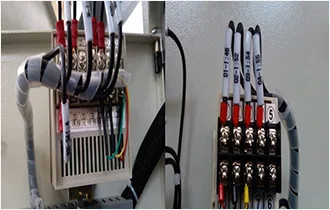

VOCSON Wire Harness Assembliés are built to meet high quality industry standards. Team members of the Wire Harness Department are trained in accordance to meet these rigorous standards.

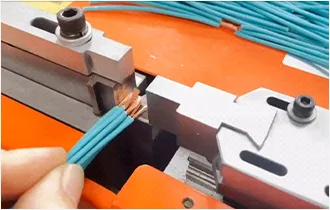

This includes instituting strict process controls for monitoring soldering , stripping, crimping,securing, etc.

Sort the individual wiring harnesses according to the standard and install them on the corresponding assembly boards

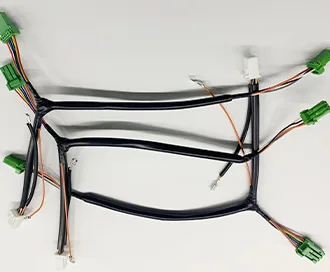

Thread wires and/or components through any required sleeving

Use wraps, ties or tape, especially at any branches

Crimp the terminal block onto the wire, especially if you have multiple wires connected to one terminal block

Packing the assembled harnesses into boxes according to customer requirements.

Ship according to customer’s delivery date

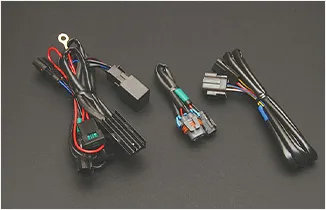

DC Female to 4 Male CcTV Camera Power Cables

Power Supply Adapter Extension Cable

A batch of wires or cables are bundled and organized by an assembly cable to link different electrical components in a power system. These cables provide simplified wirings and protection from physical damage, wear and weather conditions. You can find them commonly existed in industries like automotive, aerospace, and electronics manufacturing, where electrical connections are well-organized and protected, which is essential to enhance the performance and lifespan of your system.

Different kinds of components that are built to enable the protection and organization of electrical systems are contained in an electrical harness assembly. The following are the major components which are contained in an electrical harness assembly. The first one is wires, which provides conduction for electrical signals or energy. Secondly, another component is connectors, which works as the devices that allow the attachment of wires to components or other wires. Next one is sheathing which provides protection. It can wrap around the wires to prevent them from damage, abrasion or environmental risks.

These components work together to generate a steady and strong system to avoid electrical shorts, interference, and other problems.

Multiple benefits are offered by Harness cable assemblies in industrial applications, they are:

Harness cable assemblies play a vital role in ensuring the long- lasting performance of your power system and lowering maintenance cost in industries like manufacturing, or telecommunications.

You can take the following aspects into consideration while picking out a harness assembly for automotive or industrial applications:

You need to take cautious consideration of the above aspects to allow the proper operation and safe use of the harness assembly in the power system.

Different kinds of materials are used in the construction of a harness assembly. And each of them is selected for its special properties and performance. These materials contain:

First one, copper. These kinds of metal material are universally worked as a conductor because it is highly conductive and malleable to electrical current.

Second one, aluminum. In most cases, it is applied in devices where weight is highly stressed, including systems in aerospace or automotive industries, though its conductivity is slightly lower than copper.

Third one, PVC. It is a delicious cake for wire insulation because it is highly flexible, durable and moisture-resistant and chemicals-proof.

Last one, thermoplastic materials. Applied for protective sheathing in environments with high-temperature, they are able to endure heat to avoid melting or degrading.

It is highly crucial to pick out the matched materials so as to ensure the good performance and lifespan of the harness assembly, particularly in high-performance conditions.

Rigorous tests are performed to the harness assemblies to make sure they fit the safety and performance requirements before setup. Some commonly-used tests contain:

First one, continuity testing. It is one of the tests to ensure that the wires can be flowed with electrical signals without any interferences.

Second one, insulation testing. This type of test ensures the wires are rightly insulated to avoid electrical shock or other risks.

Last one, environmental testing. You can increase the exposure of the harness assemblies to fluctuated temperatures, mositure, and vibrations to verify they are able to endure the situations of their required use.

These tests play crucial roles in enabling the reliable performance of the harness assembly in the system and the industry regulations are complied.

You can find wire harness assemblies in a variety of industries that are shown below:

Because of their high reliability and efficiency, wire harness assemblies play indispensable roles in the above applications to ensure the products in that industry can be safely and effectively functioned.

Definitely yes. Special requirements can be met if customizing the harness cable assemblies. The custom design may include various wire gauges’ selection, insulation materials, or connectors, to fit the requirements of the electrical and environmental of the power system. Customized design services are provided by many suppliers, which enables the construction of designated harness assemblies that meet the required specifications of a power project or system.

A harness assembly used in complicated electronic devices include some major advantages:

Simplification: Various wires and cables are organized by a harness assembly into an individual unit, which enables the easy setup and maintenance.

Safety improvement: Wires are protected by harness assemblies from damage, which lowers the hazards of electrical shock, fire or interruptions.

Durability Enhancement: The cable assemblies are prevented by the protected sheathing and wraps from being exposed to harsh factors of environment, which lengthens the lifespan of the power system.

Harness assemblies play essential roles in verifying that complicated electrical systems run in an efficient, safe and reliable manner

Harness assemblies should fit the specific industrial and safety standards, ensuring the high-quality and reliable of the system. Some universally-seen ones contain:

Looking for Wiring Harnesses Assembly Services for Your Project?

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.