Tinned Copper Wire VS Bare Copper Wire: Definition, Benefits, Applications, and How to Choose

Copper wire is commonly viewed as one of the best conductors of electricity because of its great electrical and thermal conductivity. However, not all copper wires are identical. Two of the most widely applied kinds lie in bare copper wire and tinned copper wire. Although bare copper wire is usually applied in general uses, tinned copper wire provides differentiated benefits in specific conditions and industries. In this blog, we Vocson will dive into what makes tinned copper wire special, the ways it compares to bare copper wire, and the reason why it may be the better option for certain uses.

What Does Tinned Copper Wire Refer To?

Tinned copper wire refers to a copper conductor with a thin layer of metallic tin coating that works as a protective layer. The layer helps protect the copper from getting into direct contact with external factors like air and moisture, which decreases oxidation and extends the longevity of the wire in extreme conditions.

Key Characteristics

- Resistance to Oxidation: Tin stops formulating copper oxide, enhancing resistance and degrading conductivity.

- Resistance to Corrosion: The metallic tin coating safeguards the wire in humid, salty, or chemically aggressive conditions.

- Enhanced Solderability: Tinned copper wires get easier to solder, which makes them fit for electronic and electrical uses.

- Durability: The tin layer enhances the wear resistance of the wire and decreases the hazards of brittle cores.

Example Uses:

Tinned copper wires have widespread applications in marine, mining, and high-moisture settings. They are commonly employed in flexible cables and high-frequency communication systems as well.

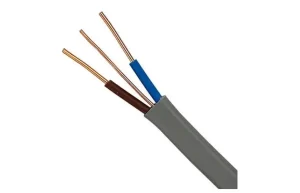

What Does Bare Copper Wire Refer To?

Bare copper wire is made from 99.9% pure copper and lacks any extra coatings. It has great conductivity and widespread uses in general electrical settings where environmental conditions are not a worry.

Features of Bare Copper Wire

- High Conductivity: Bare copper serves as one of the best materials for electrical signal and electricity transfer.

- Affordability: Because it goes through fewer production processes, bare copper wire is more cost-saving.

- Susceptibility to Oxidation: With no protective coatings, bare copper wires easily oxidize when having exposure to air, formulating a layer of copper oxide that enhances resistance and reduces performance over time.

Example Uses:

Bare copper wires have common uses in indoor setups, grounding systems, and low-humidity conditions.

Tinned Copper Wire VS Bare Copper Wire

Tinned copper wire and bare copper wire are applied for similar purposes but they are different in their resistance to environmental factors and specific use scenarios. Learning about their differences helps make a better choice for your electrical project.

Distinctions Between Tinned Copper Wire & Bare Copper Wire

To better differentiate their distinctions, let’s take a look at the differences between tinned and bare copper wires from the perspective of performance, processes, and application suitability.

1. Performance

- Oxidation Resistance: Bare copper wire is more likely to oxidise, which results in forming copper oxide that enhances resistance and decreases conductivity. Tinned copper wire, on the other hand, has a tin layer which can be against oxidation, which guarantees steady functioning in damp or salty conditions.

- Corrosion Resistance: Bare copper wire is prone to corrosion in extreme conditions like coastal regions. However, tinned copper wire has high resistance to corrosion, which enables it to be ideal for marine and industrial settings.

- Durability: Tinner copper wire has enhanced durability because of the protective tin coating, while bare copper wire is more conductive but less durable in extreme conditions.

2. Different Production Processes

Bare Copper Wire is mainly made by drawing pure copper into a wire form, while tinned copper wire starts as bare copper wire, which has a layer of tin coating with the help of a hot-dipping or electroplating process.

Are Tinned Copper Wires Better Than Bare Copper Wires?

The answer is decided by the application. Though bare copper is more cost-saving and fit for common-purpose applications, tinned copper wire provides great performance in harsh conditions.

1. Profits of Tinned Copper Wire

- Resistance to Environmental Conditions:

Because of the tin coating, tinned copper wires become the better option for damp, salty, or chemically aggressive conditions. - Longer Lifespan:

By avoiding oxidation and corrosion, tinned copper wires have an extended lifespan in comparison with bare copper wires. - Enhanced Solderability:

With the help of the tin coating, tinned copper wires get easier to solder, which decreases setup time and effort. - High-Frequency Performance:

In high-frequency uses, tinned copper wires decrease the “skin effect,” guaranteeing better signal transfer.

2. Application Case:

Tinned copper wires have widespread applications in:

- Marine settings (boat wiring).

- Mining cables for rugged conditions.

- Aerospace and auto wiring.

- High-frequency communication system.

3. Drawbacks of Tinned Copper Wire

- Cost: Tinned copper wires are more cost-consuming because of the extra manufacturing process.

- Temperature Resistance: Although fit for most conditions, tinned copper wires can tolerate a max temperature of 150°C and even up to 200°C for thicker wires.

Tinned copper wires become a great option for conditions where durability, resistance to corrosion, and lifespan remain key. However, bare copper can be a more cost-saving alternative for standard indoor setups and low-risk conditions.

Applications & Future Demands

Current Uses

- Marine & Offshore Wiring: Because of the high resistance to corrosion, tinned copper wire becomes an indispensable part of salty and humid environments.

- Industrial & Mining Devices: The copper wire can also handle wear and tear in rugged conditions.

- Renewable Energy Systems: The wire can also be applied in solar panels and wind turbines to withstand fluctuating weather conditions.

Emerging Trends

- Hybrid Coating: With hybrid coating, the new type of copper wire combines tin with silver or other metallic materials for improved conductivity and durability in high-heat conditions.

- Sustainability Initiatives: Suppliers have been developing eco-friendly tin plating processes to decrease the environmental impact.

Tinned copper wire and bare copper wire have their special benefits, respectively. However, the selection is decided by your specific demands. For conditions with high humidity, salt, or chemical exposure, tinned copper wire offers unparalleled durability, stability, and performance. In addition, bare copper wire is gradually becoming a cost-saving solution for common uses in controlled conditions.

When you choose between the two, the environment, budget, and application needs should be taken into consideration. We, Vocson, are a reliable supplier that offers premium copper wires that fit your project’s demands.

Related Reading

Comprehensive Guide to Wire Harness Prices

How to Choose the Right Electronic Wire Cables

Types and Applications of Copper Wire: A Step-by-Step Guide

Different Types of Electric Wires: Residential Application, Uses and How to Select