Home > Tinned Copper Cables

Our tinned copper cable has the copper conductor that is encased with a thin layer of tin. This layer coated with tin is helpful for the protection against corrosion, particularly in conditions that have exposure to humidity, moisture or salt. Coated with thin layer, the cable protects itself against the oxidation, which improves the durability and achieves the extension of longevity in harsh conditions. High conductivity of copper can be maintained with the help of the tin coating. Applications that require flexibility and resistance to corrosion frequently needs tinner copper cables.

| ltem Name | Cable Values |

|---|---|

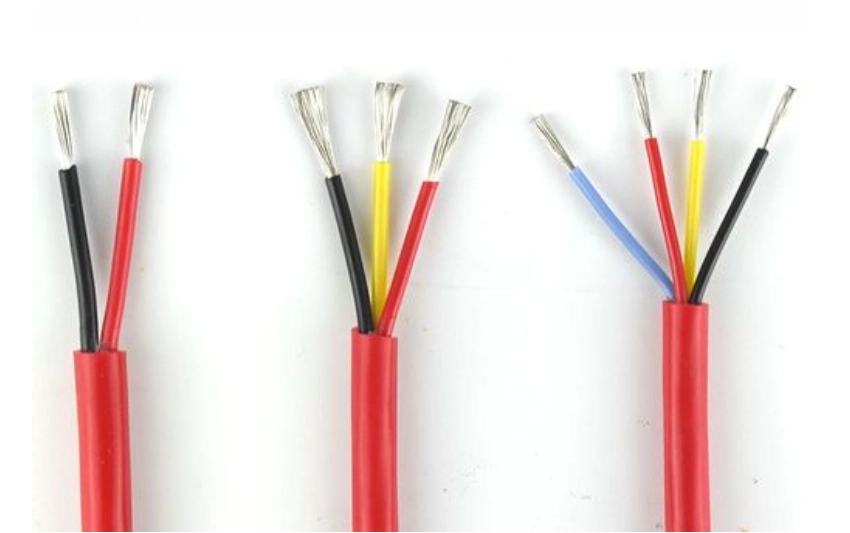

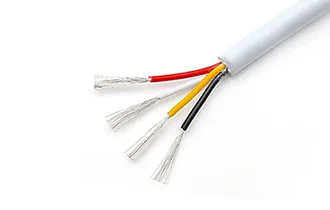

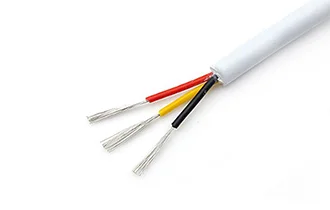

| Cable Color | White, Black, Red, Green, Yellow(Support Customization) |

| Cables Gauge | 16-30awg (Support Customization) |

| Connector Gender | Terminals, connectors, DC connectors |

| Pins | 2 - 8 Pins |

| Ways | 2 - 10 Ways |

| Conductor Material | Tinned Copper |

| Insulation Material | Silicone, PVC |

| Voltage | 0 - 300V |

| Rated Temperature | -40 - 80°C |

| Certification | UL CE Rohs |

The major differences between tinned copper wire and bare copper wire lie in a tin coating on the copper conductors in tinned copper wire. However, a bare copper wire has no tinned layer protection cover. Some differences are shown below:

Because of the nature of corrosion resistance, tin is commonly applied in copper wires. Here are the benefits of tin:

Some major benefits are listed below:

a. Corrosion-resistant: Great protection against corrosion is generated by using the tin layer coated on copper cables, particularly in conditions that have high exposure to humidity, oil and salt. This enables the copper cable to use in marine, auto and outdoor uses where bare copper cables may degrade swiftly because of the oxidation.

b. Enhanced Longevity: Tinner copper cable usually has lengthened longevity in extreme conditions because of the resistance to corrosion. With this durability, the need for maintenance and replacements is decreased, which is time-efficient and money-consuming over time.

c. Intensified Solderability: The soldering of tinned copper cable can be easily achieved with the use of tin coating because the bonding of tin is more efficiently created than bare copper wire. This generates cleaner, more durable and more stable solder joints, which plays an essential role in devices that frequent soldering is required.

d. Strong Electrical Conductivity: The tin layer on the copper cable has no great impact on the excellent electrical conductivity although it has strong resistance to corrosion. This enables the high electrical performance of tinner copper wire. What’s more, it functions durably.

e. Flexible & Durable Capability: The routing and installation of tinner copper cable will be easier to achieve in confined spaces or along complicated elements, though it has high flexibility. Along with the improved durability, the flexibility allows it appropriate for devices where the frequent motions or exposure to vibration are required.

f. Against Harsh Conditions: The copper wire is protected by the tin coating against harsh environmental conditions like high-temperature, chemical substance, and UV ray exposure. This enables tinner copper cable to be applied in devices like solar systems, offshore areas and industrial devices, where extreme environments over long periods can be achieved.

a. Barrier-Tin Coating: Working as a barrier between the copper conductor and the condition, the tin coating avoids direct exposure of the copper wire to humidity, oxygen and corrosive components, which is especially efficient in conditions where a high presence of salt is required. The conditions include marine environment, or some places where humidity and moisture matter.

b. Avoiding Oxidation: Oxidation can be caused by the exposure to air and water in copper with no protection, which results in the creation of copper oxidation. This decreases the conductivity of the copper cable and the performance is compromised. However, oxidation can be avoided with the use of tin layer since tin has fewer reactions with oxygen than copper.

c. Saltwater & Chemicals Resistance: Powerful resistance is provided by using tin coating to be against corrosive chemicals, such as saltwater. The tin layer provides protection of copper against swift degradation especially saltwater that can enhance corrosion. The degradation may be generated due to the exposure to seawater. This works the same in industrial devices, where the cable might be contacted with oils, acids or other slated substances.

d. Prevention in High-Moist Conditions: Bare copper can be corroded faster with high moisture, particularly in high-moisture conditions. And tinned copper cables are typically applied in such environment since tin layer protects moisture from reaching the copper. Therefore, the risk of corrosion from water can be reduced.

Looking Tinned Copper Cables for Your Project? We Are Ready to Support You.

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.