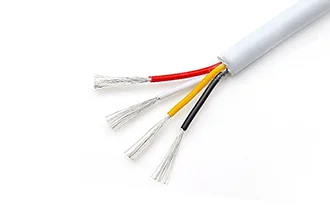

Home > Silicone Wire Cables

Our Silicone Wire Cables have Exceptional insulating properties, flexible, high temperatures and better resistance to thermal shocks, and also get UL, Rosh, CE certificates.

| ltem Name | Cable Values |

|---|---|

| Cable Color | White, Red, Black, Green, Blue,gold, Yellow, etc. (Support Customization) |

| Cables Gauge | 4-30awg (Support Customization) |

| Cables Pins | 2-10 Pins |

| Waterproof Rate | IP67 |

| Cable Outside Diameter | 5-14mm (Support Customization) |

| Conductor Material | Copper, Tinned copper |

| Insulation Material | Silicone |

| Max Voltage | 300V(Based on customer's needs) |

| Rated Temperature | 200°C |

| Certification | UL CE Rohs |

Silicone wire and cable provide multiple profits, which includes:

Silicone wire and cable are able to handle temperatures typically varying from negative 60°C to +200°C. Certain customized silicone wires can endure even higher temperatures which are up to 250°C or more. All these are decided by the application. The extensive range of temperature makes silicone wire and cable perfectly fit for conditions where extreme heat or cold occur, including:

Yes, silicone wires are safe for outdoor application because of their resistance to harsh conditional factors, including:

Silicone wire is especially matched for auto uses because of the profits below:

Yes, a silicone cable typically has higher flexibility than cables with other kinds of insulation. This flexibility is benefited from the qualities of silicone rubber, which maintains its softness and pliability even in cold weathers. The flexibility of the silicone cable enables it to be fit for scenarios where the cable is bended, twisted, or in frequent movement, including robotics, automation devices, and mobile machinery

Silicone wire has high durability and can be used for years, even in extreme conditions. Its lifespan is attributed to multiple factors:

Silicone wire can be used for decades if it is in proper setups and applied within its specific temperature and conditions limits. This makes it a long-term solution for high-demanding electrical uses.

Yes, given it is graded for the system’s voltage levels, a silicone cable can be applied in high-voltage settings. Brilliant electrical insulation and high voltage endurance can be provided by silicone insulation with no risk of breakdown or arcing, but it is crucial to ensure the matched voltage rating of the cable for the specific application.

Follow the safety considerations is a must when using the silicone wire:

Silicone able and Teflon (PTFE) wire provides brilliant abilities of heat resistance, but they possesses various properties:

The selection between silicone and Teflon wire is decided by the specific demands of the application like flexibility, chemical resistance, and temperature range.

The Termination of silicone wire includes the connection of the wire to another electrical element or appliance in a secure and reliable way. Some universal techniques for the termination of silicone wires are shown below:

a. Crimping

Crimping acts as one of the most reliable ways for the termination of silicone wires, specifically for auto and industrial settings. It contains the compression of a connector or terminal onto the wire applying a crimping tool.

Crimping is fit for the creation of swift and durable links that can ensure vibration and mechanical stress.

b. Soldering

Through melting solder onto the exposed wire and terminal or connector, a strong electrical connection is created when soldering. This technique is widely applied in electronic devices. the way to solder silicone cables are shown below:

Ensure a careful management of heat to prevent the damage to the silicone insulation since it has a lower melting point in comparison with to other materials.

c. Screw Terminals

Screw terminals remain a handy choice for achieving temporary or adjustable connections. How to apply screw terminals with silicone wires are shown:

Screw terminals are widely applied in a circuit board, a junction boxe as well as terminal blocks, where flexibility and easy connection play a necessary role.

Looking Silicone Wire for Your Project? We Are Ready to Support You.

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.