Home > PVC Wire Cables

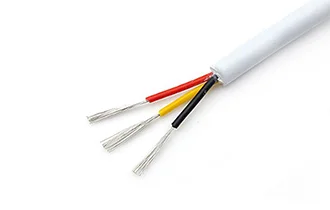

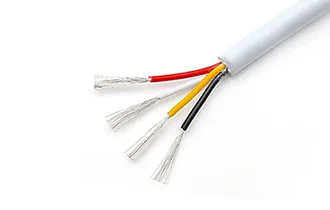

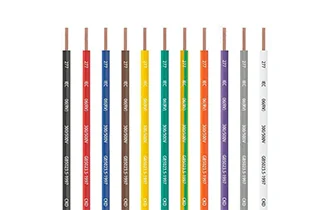

PVC Cables can be used in many applications, from fixed wiring to flexible installations. We provide full range PVC wire cables for your projects. Our cables can be used in a variety of applications, such as LED Lighting, Solar energy, auto, computer.

| ltem Name | Cable Values |

|---|---|

| Cable Color | White, Red, Black, Green, Blue,gold, Yellow, etc. (Support Customization) |

| Cables Gauge | 16-30awg (Support Customization) |

| Cables Pins | 2-10 Pins |

| Cable Outside Diameter | 5-14mm (Support Customization) |

| Conductor Material | Copper, Tinned copper |

| Insulation Material | PVC |

| Max Voltage | 300V(Based on customer's needs) |

| Rated Temperature | -40-80°C |

| Certification | UL, Rohs |

PVC wires are delicious cakes for electrical systems because of the following:

Yes, PVC cables can be employed outdoors, but there are some limitations:

PVC cables and cables are different from silicone or rubber-insulated wires in multiple aspects:

PVC cables have wide applications for data transfer because of multiple profits:

To lengthen the longevity of PVC wires, the following storage guidelines can be used:

Yes, PVC wires have some fire safety natures:

To terminate PVC cables in the right way, follow the steps:

When opting for PVC cables for industrial settings, the following factors should be considered:

While PVC–insulated cables have multiple advantages, they have certain downsides as well:

PVC cables can be applied for underground setups, but extra protection is required:

PVC wires can be employed in marine conditions for some uses, but there are some limitations:

For safe installations of PVC cables in residential applications:

Flame-retardant PVC wires are treated to tolerate ignition and prevent the spread of flames. These cables are widely employed in applications where fire safety is a key, which includes

For safe installations of PVC cables in residential applications:

Looking PVC Wire Cable for Your Project? We Are Ready to Support You.

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.