How to Choose UL2468 Wire Cable, A Detailed Guide

As one of the most common types of cable in different electrical and electronic devices, UL2486 wire able is typical ubiquitous in electrical systems that require low voltage, because of the flexibility, durability and the fit for safety compliance. In applications like consumer electronic devices, telecommunications and auto machinery, you can find the common use of this wire cable featuring flat and consisted of 2 or more than 2 conductors. We will specifically guide you to pick out a perfectly matched UL2468 wire cable to your electricity system.

The Definition of UL2468 Cable

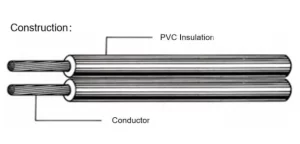

Composed of several PVC insulated copper conductors, flat and ribbon-like UL2468 wire cable is usually employed in low voltage applications that require internal wiring. These devices have great concern on the flexibility and simple & easy setup. The cable is ensured to fit the safety performance standards, which is achieved by the designation coming from the UL certification. This certification plays crucial roles in making sure the compliance of the cable with electrical codes and fitness for especially devices.

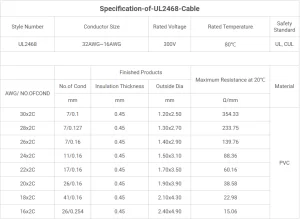

Constructed with flatness, easy routing required in limited spaces is allowed for the UL2468 wire cable, which allows it to greatly fit for electronic devices, appliances and autos that require internal wiring. Different gauges are available ranging from 20 AWG to 24 AWG, and 20 and 24 are the most universal types. With the great availability, a wide range of choices are provided according to the specific needs.

Major Characteristics of UL2468 Wire Cable

The major features play crucial roles in affecting the selection of the matched UL2468 wire cable, so it is essential to learn about the characteristics firstly:

- Flat Configuration: Because of the flatness and ribbon shape, UL2468 wire cable can be easily routed in restricted places and along complicated curves with no occupation of too much space.

- Insulation with PVC Material: Built with durable PVC, UL2468 wire cable provides strong protection against physical damage, abrasion and humidity. Electrical insulation and heat resistance are provided by PVC materials as well, which enables safe operation as time goes by.

- Various Conductors: Equipped with often 2 or more conductors, UL2468 wire cable enables easy separation, which enables it to be widely applied in different electrical installations.

- UL-Certified: A UL-certified UL2468 wire cable is highly recommended for the reason that it ensures industrial safety and performance standards, which enables the reliability for various electronics and systems.

- Resistance to Heat: Designed with high-temperature rated feature, this wire cable is capable of ensuring temperature ranging from minus -20°C to 80°C, which enables the suitability for different conditions where moderate heat resistance is a key.

VOCSON UL2468 #22AWG x PH1.70, 2P-12P

VOCSON UL2468 #20AWG x 2P

Considerations to Pick Out UL2468 Wire Cable

1. The Type of Applicable Industry

The first aspect you need to consider is the identification of the specific uses of the wire cable. Perfectly fit for internal wiring, UL2468 wire cable is universally applied for electronic devices and electrical systems, which include:

- Electronic Devices: Because of the high flexibility and simple & easy setup, UL2468 wire cable is widely applied in audio-visual systems, high-performance gaming devices and other consumer electronics.

- Auto Application: Easy integration of wire cable into auto systems can be easily achieved due to the flatness, which makes it particularly fit for the routing in limited spaces in dashboards or the panels of doors.

- Home Appliance: UL2468 wire cables play high decisive roles in the internal electrical wiring required by most household appliances like AC, microwaves and fridges.

- LED Lighting: UL2468 wire cables are ubiquitous in LED lighting systems because of the flexibility and capability to withstand low voltages.

2. Wire Gauge & Voltage Rating

The gauge of the wire cable refers to the wire thickness and has impacts on the current amount the wire cable can carry with no overheated issue.

Some divisions are:

- The 20 AWG gauge is appropriate for high-current applications like automotive electronic devices or larger equipment. However, you can see 22 AWG gauge frequently use in audio systems, telecoms and small equipment. What’s more, applications that require low current, such as LED lighting and mini electronic devices, are used with 24 AWG gauges.

Tip: Ensure you select the appropriate wire gauge for your device. It a wire used is too thin, the desired current may result in overheated and other potential risks.

3. Insulation & Material

In high-demanding environments, the durability and performance of a wire cable is achieved by its materials insulated with PVC, which is selected for its robustness and electrical insulation properties. Some features mentioned below are provided by PVC:

- Abrasion-resistant: The terminal wire cable can be protected by the PVC-insulated encase against physical damage when installing and operating.

- Heat-resistant: Moderate temperature fluctuations can be withstood by the wire cable with no melting or degradation, within the operational temperature range from minus -20°C to 80°C.

- Chemical-resistant: Great resistance to oils and chemical substances are achieved by PVC insulation, which enables the perfect use in auto or industrial conditions.

Make sure the material of the wire cable’s insulation is capable of withstanding environmental factors in which it will be utilized, for the selection of UL2468 wire cable. Take examples, Indoor conditions are the perfect places for using PVC insulation. However, the insulation may not function well in extreme weather conditions or outdoor uses with no extra protection.

4. Length & Conductor Quantity

Considerations of the length and quantity of conductors in UL2468 wire cable also play crucial roles. Below is the explanations:

- Length: Appropriate length can promise the coverage distance between elements with no too much pressure on the wire cable. Thus, it is crucial to calculate the distance precisely and flexibly.

- Conductor Quantity: 2 or more than 2 conductors are equipped with UL2468 wire cable, which enables the transmission of various signals or electricity by using the identical cable. Ensure the selection of the quantity of conductors fit the specific requirements of your electronic system.

A two-conductor may be required to enable the connection between both the positive and negative terminals in a speaker system. Extra conductors may be required in more complicated systems like auto wiring or appliance monitoring system.

5. Environmental Factors

Long-time and smooth performance of your electrical system can be ensured by learning about the places where the wire cable will be applied. Specifically built for applications that require low voltage, UL2468 wire cable is still required to resist to heat, humidity and vibration when picking out the matched cable.

- Temperature: A high-temperature environment require durable and heat-resistant wire cable to withstand the desired temperature range.

- Humidity: Extra insulation or water resistance may be needed for the outdoor conditions where the wire has high exposure to humidity.

- Vibration: The wire cable may have exposure to continuous vibration in devices like auto or heavy machines, so ensure the proper secure of the wire cable to prevent damage or tear as time goes by.

6. Safety Compliance

The reason why UL2468 wire cable is highly popular lies in he UL certification. The “UL” designation represents the wire cable has conducted the tests for safety and performance standards required by electrical systems. Remember to check the must-needed UL markings when choosing a UL2468 wire cable, particularly if the device is subject to regulatory monitoring like commercial builds or auto devices.

In addition, compliance with other local electrical codes and standards may need to be confirmed, which depends on the specific region or industry.

Careful consideration of different aspects plays important roles in the selection of the matched UL2468 wire cable for your electrical system. Aspects include the type of device, wire gauge, insulated material, and environmental factors. A secure and efficient electrical installation can be promised by learning about the special requirements of the application and the capabilities of UL2468 wire cable. Also, it is crucial to guarantee the quality and reliability of the required UL2468 wire cable when purchasing. VOCSON is a great alternative, we’re a trusted brand famous for providing a wide range of high-end terminal wire harnesses and other electrical elements that fit the safety industrial standards. The products manufactured by us offer durability and performance needed for different applications, which ensures the steady and reliable operation in your electrical systems.

High flexibility, durability and UL certification can be achieved by applying UL2468 wire cable no matter the applications, such as consumer electronic equipment, auto systems or LED lighting. Informed decisions can be made using this detailed guide and with this, the smooth and reliable operation of electrical systems can be highly ensured.

Related Reading

UL2464 Wire Cable: 5 points before you select

How to Select 3G 6 sq mm Cables for the Connection of Electric Hobs