Home > Electrical Wire Cables

Our electrical Wire Cables have Exceptional insulating properties, flexible, high temperatures and better resistance to thermal shocks, and also get UL, Rosh, CE certificates.

| ltem Name | Cable Values |

|---|---|

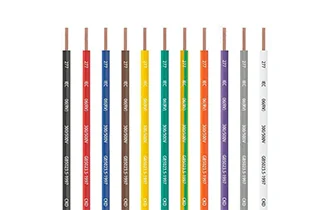

| Cable Color | White, Red, Black, Green, Blue,gold, Yellow, etc. (Support Customization) |

| Cables Gauge | 4-30awg (Support Customization) |

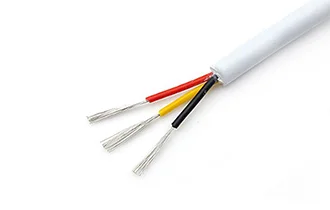

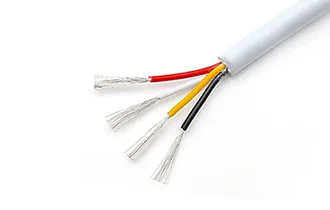

| Cables Pins | 2-10 Pins |

| Cable Outside Diameter | 5-14mm (Support Customization) |

| Conductor Material | Copper, Tinned copper |

| Insulation Material | Silicone PVC |

| Max Voltage | 300V(Based on customer's needs) |

| Rated Temperature | 200°C |

| Certification | UL CE Rohs |

To sum up, a wire defines as an individual conductor and cables are a group of wires, and cords are flexible cables typically applied for linking devices to power sources.

Multiple kinds of electrical wire are shown below, with each serving various purposes:

Multiple essential purposes are shown below:

The insulation type used is decided by various applications. Some universal insulation materials contain PVC, rubber, and Teflon.

The most commonly used materials cover:

The selection of the matched electrical cable is decided by multiple factors:

Broken electrical cords can generate serious safety risks. Some signs need to be watched for:

Old electrical cables or cords cannot be directly thrown into a regular trash bin because of the harmful impact they generate on the environment. Some proper ways to dispose of them are listed:

Handling electrical cords safely plays a crucial role in avoiding accidents, injuries, and fires. Multiple safety precautions can be followed:

Tinned copper wire functions as a copper wire coated with a thin layer of tin to elevate its durability and corrosion resistance. The main benefits include the following:

The factors below should be considered for the selection of an electrical cord for outdoor use:

The third prong on an electrical cord refers to the grounding prong which is essentially safe for providing a path for electrical current to go through securely into the ground to avoid a fault like a short circuit. This is helpful to avoid electric shock and lower the fire hazard. Below show how the third prong functions:

Tip: An adapter should not be used to bypass the grounding prong since the safety features of the electrical cords will be compromised.

Yes, some kinds of electrical cables are built explicitly for underground applications. These cables are generally applied to carry electrical power from the main construction to outdoor structures, such as sheds, garages, or outdoor lighting. There are 2 universal kinds of underground electrical cables, they are:

Tips: Following up on local building codes plays a crucial role in burying electrical cables to ensure they are set up at the correct depth and greatly protected against physical damage.

Looking Electrical Wire Cable for Your Project? We Are Ready to Support You.

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.