We deliver precise, high-quality, and efficient Connector Cable Products as your needs.

| Connector Cable Item Name | Cable Harness Values |

|---|---|

| Connector Cables Color | White, Red, Black, Green, Blue, Yellow, etc. (Support Customization) |

| Connector cable Gauge | 20AWG,22AWG,24AWG(Support Customization) |

| Connector Cable Pins | 2-10 Pins |

| Cable Outside Diameter | 4mm, 6mm (Support Customization) |

| Waterproof Rate | IP67 |

| Cable Outside Diameter | 4mm, 6mm (Support Customization) |

| Conductor Material | Copper, Tinned copper |

| Insulation Material | PVC |

| Max current | 0-12A(Based on customer's needs) |

| Rated Temperature | -40-80°C |

| Male Cable Length | 15CM,30CM,60CM,100CM(Support Customization) |

| Female Cable Length | 15CM,30CM,60CM,(Support Customization) |

| Net Weight | 0 - 21g |

| Certification | Rohs |

Networking

Connector cables are specifically designed to ensure a connection that is very snug and dependable, which is designed for the applications of the equipment.

Cable fabrication was explained earlier; each cable is manufactured using special layers to ensure strength and proper operation. The first layer in a wire used to manufacture a connector is comprised of materials that are excellent conductors of electricity, such as copper or aluminum. An insulating layer of materials such as PVC or Teflon, among others, then encloses this conductor with a view to keeping electrical discharges at bay and further safeguarding the cables from environmental aspects.

In most cases, the design of the cables incorporates a protective shield for maximum safety and the maintenance of clear signals in the course of transmission. It ensures no interference may cause a hitch in communication. The outer layer of the cable is generally hard and fabricated from rubber or nylon, for example, to protect the cable from physical damage and harsh environmental conditions.

It is all types of connecting cables – from simple USBs and power cords to their complex cousins like Ethernet or fiber optics. Each and every cable is manufactured with the highest degree of technical standards and safety requirements. In our company, we want to make sure that each cable created is perfect, safe, and efficient enough for all your needs.

The following represent several of the safety standards that connector cables should fulfill to ensure that the cables are safe and effective:

A connector cable harness is a systematic and integrated arrangement of multiple connector cables or wires transmitting electrical power or signals. It could also be referred to as a wire harness, cable assembly, wiring assembly, or wiring loom. The assembly has been set up in order to simplify the setting up of electrical systems by bundling numerous wires into a single organized bundle. Every single wire in the cable harness plays a different role, but once bundled up, they form a whole, making it one product that answers simply to the complex wiring used in a system.

Just like the good conductors used in the manufacture of individual connector cables, the wire used in cable harnesses is often made of copper or aluminum and insulated using materials like PVC or Teflon to prevent an electrical discharge and protect against environmental factors. However, instead of dealing with each wire individually, a cable harness assures bundling the various wires together, typically using electrical tape, conduit, or a mixture of sleeving and cable ties.

This ordered grouping not only makes the process of installation easier but also promotes safety by reducing the mess of loose wires—something that is an easy way to make a design unprofessional, cause intermittent issues because of loose wires, or present serious hazards through high currents in small wires. Furthermore, it reduces the chance of a short since physical protection is usually robust and covers an entire harness.

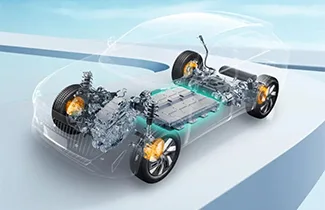

Whether used in the automotive or aerospace industry, ordinary household appliances, or electronic gadgets, cable harnesses for connectors enable many connections to be controlled more efficiently and safely. They are designed for particular configurations and requirements which can ensure the proper connection of various system components safely and reliably.

A wire connector harness, also commonly named a cable harness or wiring assembly, is an organized set of electrical wires or cables that are bound together to transmit either signals or electrical power in complex systems. The design point of the harness is to make setup for electrical systems easier through the ability to house several wires into one single unit, therefore saving on space requirements during installation, making installation easy, and also maintaining the harness.

Wire harnesses are put together from wires and cables, and in this organization, it is done with sleeves, electrical tape, cable ties, or other products that protect and hold these components. Such organization guards wires against heat, moisture, and abrasion, among other forms of environmental hazards; hence, it prevents them from tangling up into a set of components.

The wire connector harness can be customized to meet a large number of areas: from automotive electrical systems to aircraft, and industrial machines to consumer electronics, all of which demand multiple electrical connections.

What distinguishes a connector cable from an ordinary cable is the fact that it is provided with connectors to allow electronic connectivity and disconnection without soldering or manual wire wrapping. Normally, such cables are better built, rated for more power and data rates, higher in terms of construction, and able to sustain the strains of multiple connections and disconnections. They are really useful when some equipment needs to be frequently moved or changed, especially for a data center and for multimedia setup applications.

Proper disposal of old cables and harnesses involves:

Hazardous Waste Disposal: Consider hiring hazardous waste disposal services if your cables contain harmful materials, especially lead.

Choosing the correct connector cable or harness is an involved process and should start with a definition of your requirements and under what conditions the cable must function. Begin by taking the proper electrical requirements, such as voltage and current, so that the harness or cable you select can handle the expected load without the possibility of heating up and failing. This is important not only from the point of view of safety but also from ensuring the longevity and reliability of the cable.

What physical environment will the cable be in? The major determinant of the choice of cable or harness includes whether it will be exposed to chemicals, extreme temperatures, or mechanical stress that may require the cables to have added features like UV resistance, flame retardance, or reinforced sheathing. Such protections are crucial for the cables used in severe environments or outdoors to prevent premature wear and ensure operational reliability.

Another very crucial factor is connector compatibility. The connectors should make an absolute match with the ports and the terminals of the devices connected in shape and pin configuration, to yield a connection that is safe and functional. Selections should be made within the latest standards applicable for data transfer applications, like USB or Ethernet, to achieve proper maximum speed and the least possible time of data transfer.

Lastly, always go for approvals from well-known and recognized standard bodies for cables and harnesses; these are not mere formalities but benchmarks to ensure the product follows stringent safety and quality requirements. Look for high-quality material cables to provide strong insulation and shielding to the cable from environmental and electromagnetic interferences, thereby enhancing general performance and longevity.

For longer life and assurance of safe connector cables, adopt a strict early preventative practice. Regularly check your cables for signs of damage, like fraying, loose connections, or broken insulation, which you will notice while they are in the making. So, briefly highlighted below are the ways you can maintain and safeguard your cables.

Maintenance Practices:

Safety Procedures:

Troubleshooting Tips:

Looking for Affordable Connector Cables for Your Project?

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.