Comprehensive Electronic Wires Selection Guide (8 Key Points)

Electronic wires form the underpin of modern electrical and electronic systems, which allows for the seamless signal and power transfer These wires, especially engineered for low-voltage and weak-current uses, play a vital role in industries varying from telecommunications and auto to consumer electronic devices and renewable energy. This detailed guide dives into the construction, performance, uses, and evolving trends in electronic wires to lead you to make wise decisions for your electrical projects.

What do electronic wires refer to?

Electronic wires refer to insulated conductors that are crafted to transfer weak electrical currents. Different from power cables engineered to withstand high voltages and robust currents, electronic wires are optimized for precision, efficiency, and safety in low-electricity systems.

Features of Electronic Wires:

- Low Voltage Transfer: The wires are built for safe functioning in systems where minimal electrical current is needed.

- Multifunctionality Across Industries: From home devices to sophisticated communication networks, electronic wires play an indispensable role.

- Material Range: The wires include bare copper, tinned copper, and aluminum to fit specific use practices.

- Premium Insulation: The wire usually has PVC, silicone, or polyethylene coating to guarantee safety and extended lifespan.

Example Case:

In smartphones, electronic wires link different internal elements, which guarantees steady electricity delivery and data transfer while maintaining compactness and durability.

The Electronic Wire’s Construction

Electronic wires are comprised of two primary components. One is the conductor that transfers electrical signals, and another is the insulation jacket that offers safety and protection.

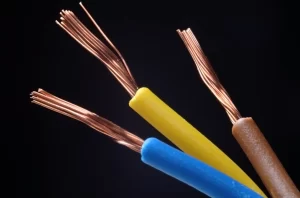

The Conductor

The conductor formulates the core of the wire and decides its conductivity and application suitability. Universal materials involve:

- Bare Copper: This type of copper is known for its high electrical conductivity, and it is commonly applied in electronic wires for general uses.

- Tinned Copper: It has a layer of tin coating that has resistance to corrosion. It is fit for damp or extreme environments.

- Aluminum: This kind of material is lightweight and cost-saving. Conductors made of aluminum are applied for specific industrial uses.

- Copper-Clad Steel: It combines the tensile strength of steel with the conductivity of copper, which makes it fit for mechanical stress applications.

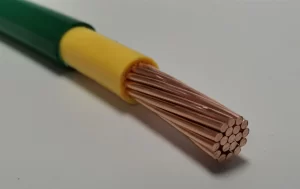

The Insulation Jacket

The insulation jacket sheaths the conductor from external elements, guaranteeing electrical safety. Welcomed insulation materials involve:

- PVC that has widespread applications for its affordability and versatility.

- Silicone that handles harsh temperatures, making it fit for auto and industrial applications.

- PE that has outstanding dielectric properties, making it preferred for high-frequency signal transfer.

- LSZH that decreases toxic emissions during fires, improving safety in enclosed conditions.

What Are the Important Roles of Metrics?

The evaluation of the performance metrics of electronic wires makes sure you pick out the best wire for your demands. These metrics include electrical, mechanical, and thermal properties.

Electrical Performance

- Electronic wire has high conductivity which determines how effectively the wire transfers electrical signals.

- Also, the insulation resistance helps minimize leakage currents, which ensures system efficiency and safety.

Mechanical Natures

- Flexibility: Crucial for applications requiring frequent bending, such as robotics and wearable technology.

- Tensile Strength: Indicates the wire’s ability to withstand physical stress without breaking.

Thermal Performance

- Its ability to resist high temperatures defines the operational temperature range of the wire.

- The capability of heat dissipation helps prevent overheating, guaranteeing consistent performance even in high-load settings.

Case Study:

In auto wiring harnesses, wires must exhibit high conductivity, resistance to vibration, and thermal stability to guarantee reliable performance under extreme environments.

Kinds of Electronic Wires

Electronic wires are designed in different kinds, each customized to specific uses and requirements.

Triplex Wires

- Applied in single-phase service drops from utility poles to buildings.

- Usually involve 2 insulated aluminum wires and 1 bare neutral conductor.

Main Feeder Wires

- Link the service weather head to the primary distribution panel.

- Built with stranded THHN or THWN wire, which is able to withstand heavy loads.

Panel Feed Wires

- Power primary junction boxes or circuit breaker panels.

- Usually made with THHN wire with black insulation, crafted to monitor high currents in a safe way.

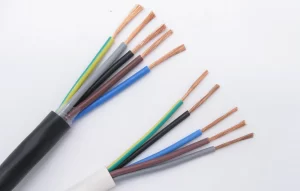

Non-Metallic Sheathed Wires

- Widely applied in residential wiring.

- Comprise 2 or 3 insulated conductors and a bare ground wire enclosed in a flexible plastic sheathing.

Single-Strand Wires

- Fit for electrical setups where wires are drawn through conduits.

- Commonly employed in industrial systems for flexible setups.

How to Opt for the Correct Size of Wires?

Wire size has a direct impact on safety and performance. A step-by-step instruction is listed below to help opt for the right size:

- The Diameter should be measured by applying a caliper to decide the diameter of a single strand.

- Circular Mils, also referring to standard cables, should be checked to find the circular mils for the measured diameter.

- Calculation of the Total Capacity: The circular mils should be multiplied by the quantity of strands to decide the total capacity of wires.

- For long distances, a larger gauge should be chosen to minimize voltage loss.

Pro Tip:

Oversizing wires not just decreases resistance but also improves system efficiency, particularly in high-electricity or long-distance uses.

Labeling & Standards for Electronic Wires

Wire labels deliver crucial information about the properties of a wire, which guarantees the compatibility with your application.

Universal Labels:

- THHN/THWN Codes

- T means thermoplastic insulation.

- H refers to heat resistance.

- W means wet location rating.

- N defines as nylon coating for durability.

- Voltage & Current Ratings: It indicates the max capacity the wire can withstand in a safe way.

- Conductor Material Indicators that are marked as “CU” for copper or “AL” for aluminum.

Uses of Electronic Wires

Electronic wires are crucial across industries, which allows for critical functioning and innovations.

Consumer Electronic Devices

- The wires are commonly found in equipment such as TVs, speakers, smartphones, and gaming consoles.

- The wire also allows for accurate and reliable signal transfer.

Auto Systems

- Electronic wires also have widespread uses in wiring harnesses for vehicles, which ensures efficient power distribution and signal transmission.

- It is vital for safety systems such as airbags and advanced driver-assistance systems (ADAS).

Renewable Energy

- The wire plays a crucial role in renewable energy systems like solar panels and wind turbines, which guarantees resilience from weather changes.

- Specialized wires are engineered to withstand different currents and high voltages.

Industrial Automation

- The wire works as an integral part of control systems, machinery, and robotics, where flexibility and durability are key.

- Wires must be capable of handling electromagnetic interference and mechanical stress.

Communication Networks

- Electronic wires are employed in Ethernet cables, coaxial cables, and fiber-optic systems for high-speed data transmission.

- It is built to minimize signal loss and interference.

Environmental Considerations & Innovations

As the industry evolves, environmental sustainability has become a significant focus in wire manufacturing.

Eco-Friendly Insulation

- LSZH wires are gaining popularity for reducing toxic emissions during fires.

- Recyclable insulation materials are being developed to minimize waste.

Energy-Saving Production Process

- Producers have been adopting green processes to decrease the carbon footprint of wire manufacturing.

Smart Monitoring Systems

- Advanced wires now involve embedded sensors for real-time monitoring of electrical systems where safety and maintenance efficiency can be enhanced.

Where to Invest in Premium Electronic Wires?

Opting for the appropriate manufacturer is crucial for guaranteeing quality, compliance, and durability. We Vocson provide a comprehensive variety of electronic wires built to fit the highest industry standards. Our products are designed for diverse applications, offering reliable and long-lasting solutions for consumers and professionals.

Electronic wires serve as indispensable elements worldwide nowadays, efficiently and precisely powering devices, systems, and industries. Learning about their construction, performance metrics, and uses allows you to make wise choices that fit your specific demands.

Related Reading

How to Choose the Right Electronic Wire Cables

Different Types of Electric Wires: Residential Application, Uses and How to Select

How to Select 3G 6 sq mm Cables for the Connection of Electric Hobs