Home > Circle Cable Wires

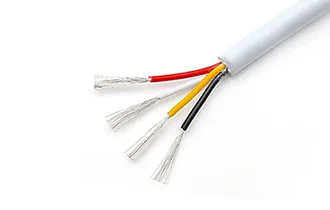

Designed with a circular cross-section, a circle cable works as an electrical cable that carry electrical power or signals. The cable is able to accommodate several conductors inside an insulated shielding due to the round shape. This allows the intensified protection, flexibility and durability. A circle cable can be easily bended, coiled and routed with the circular design. This allows the cable to perfectly fit for devices where they are frequently moved or tightly bended because of confined spaces. Universally applied in different industries like household commercials, for functioning devices, machines and appliances, circle cables have strong construction and capability to ensure wear and tear, which allows them to fit for conditions that require heavy-duty tasks, such as construction sites.

| ltem Name | Values |

|---|---|

| Color | White, Red, Black, Blue, Green, Orange(Support Customization)) |

| Gauge | 12 - 30AWG(Support Customization) |

| Voltage | Up to 300V |

| Waterproof | IP65 - IP67 |

| Conductor Material | Copper, Tinned copper |

| Insulation Material | PVC, Silicone |

| Max current | 0-12A(Based on customer's needs) |

| Rated Temperature | -40-80°C |

| Cable Length | Custom for your projects |

| Certification | UL, CE, Rohs |

Below are the major advantages of applying circle cables:

a. Reinforced Flexibility: Easy bending, coiling and maneuvering can be achieved because of the circular cross-section of circle cables, allowing them to greatly adaptable in conditions where cables are required to navigate along blocks or through confined spaces. This high flexibility allows them to perfectly fit for dynamic uses like portable devices or mobile machines.

b. Durable & Wear-proof: Featuring several layers of insulation and protective shielding, stronger resistance to external damage, abrasion and environmental conditions can be provided by using circle cables. This durability allows the cable to handle harsh environments where heavy-duty machines are used, or where exposure to humidity and extreme conditions.

c. Intensified Heat Dissipation: Better airflow around the cable is allowed due to the round shape of circle cables, which facilitates effective heat dissipation. This decreases the hazard of overheated issues, especially in high-current or constant-apply devices, which intensifies the safety and lifespan of the circle cable.

d. Decreased Cable Stress: More balanced mechanical stress is distributed by circle cables across the construction, which offers greater reduction of strain. This decreases wear at connected points, which reduce the suffering of damage or internal breakup in the long run.

e. Higher Current Bearing Capacity: The accommodation of several conductors is allowed with the help of the round design of circle cables, which offers stronger bearing capacity of high current. This allows them to fit for devices that require the transfer of much more power, such as industrial devices or large equipment.

f. Multifunctional Usages: Applied in a variety of applications ranging from home appliances to outdoor lighting, circle cables are durable, flexible and capable of carrying substantial electrical loads, which allows them multifunctional enough to fit the demand of residential and commercial conditions.

g. Organization & Aesthetic Purpose: Simple and convenient coiling and storage can be achieved by using circle cables with the round shape. This helps decrease tangling and clutter, making them more appealing and organized visually, particularly in installations where organization and tidiness matter, such as offices or household theaters.

h. Weatherproofing: Usually built with tough insulation materials that are capable of ensuring harsh outdoor conditions such as windy, rainy and strong UV rays, circle cables are ideally applied for outdoor use in environments where heavily rely on durable and weather-resistant connection of electricity.

Several major aspects show the differences between circle wire cord and flat wire cord:

a. Shape & Structure: More space is allowed inside the insulation for several wires and protective layers with a circular cross-section. Because of the round shape, additional structural integrity and flexibility is provided. On the other hand, with the wires organized side by side in a single layer, flat wire cord design with a flat shape is more organized but is less durable in a long run because of the lack of extra protection layers.

b. Flexibility: The coiling and routing of circle cable cord can be easily achieved in confined spaces. Also, smooth bending with no damage to internal wires is allowed with the help of the round design, which allows them to perfectly fit for dynamic conditions where require frequent movement of the cable. Flat cable cord, on the contrary, has fewer flexibility and tend to kink or bend, particularly in uses where require frequent movement or sharp bends, which makes them better fit for stationary installations where involves minimal movement.

c. Durability: Because of the design, circle wire cord provides higher durability, allowing for more insulation and protective layers along the wires. This allows more wear and tear resistance, involving abrasion, humidity and fluctuated temperatures. However, flat extension cords have less durability because of the lack of extra protection layers spotted in circle cords. Flat extension cords have more likelihood to experience bending, stress or other forces, which allows them to less appropriate for heavy-duty machines.

d. Heat Dissipation: With the round shape that allows for more airflow along the cable, circle cable cord features better heat dissipation, which decreases the risk of overheating, particularly in high-current or constant-use devices. However, flat cable cord is less efficient at dissipation because of the organized and layered structure. This allows flat cords to easily overheated in high-electricity applications.

Circle Cable Wire for Your Project? We Are Ready to Support You.

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.