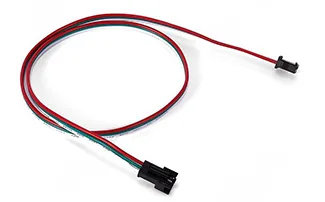

VOCSON provide you precise, high-quality, and efficient Cable Harness products for your projects.

| Cable Harness ltem Name | Cable Harness Values |

|---|---|

| Cable Harness Color | White, Red, Black, Green, Blue, Yellow, etc. (Support Customization) |

| Cable Harness Gauge | 0 - 36 AWG(Support Customization) |

| Cable Harness Pins | 2-10 Pins |

| Waterproof Rate | IP67 |

| Conductor Material | Copper, Tinned copper |

| Insulation Material | PVC |

| Max current | 0-12A(Based on customer's needs) |

| Rated Temperature | -40-80°C |

| Male Cable Length | 15CM,30CM,60CM,100CM(Support Customization) |

| Female Cable Length | 15CM,30CM,60CM,(Support Customization) |

| Net Weight | 0 - 21g |

| Certification | Rohs |

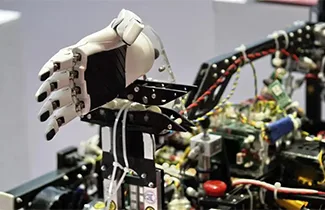

Medical Equipment

For the manufacturing process of making it, manual production is generally cheaper than automation, and there are generally the following steps: first, wiring through the sleeve, second, using fabric tape, third, pressing multiple wires into one terminal, fourth, inserting one sleeve into another, and finally, fixing the strands.

Yes, cable wire harness is made of some durable materials, such as wire conduits, rubber, vinyl and so on, which can be bundled together to transmit signals and electricity.

It has many benefits, for example, many planes or cars can use them to extend several kilometres. It can protect wires and cables from moisture and abrasions. What’s more, it will optimise the usage of space and decrease the risk of a short. If you bring our product, you will find it’s easy to install. It is also used in the studio, used to transmit audio signals.

Cabling harnesses come in many varieties as the market demands, common ones such as RF harnesses, which are mainly used for high-frequency signal transmission and suitable for wireless communication equipment and radar systems. Flat harnesses are widely used for computer and household devices, EMI shielded harnesses can reduce external electromagnetic interference through the shielding layer to ensure the stability and reliability of signal transmission.

Depending on the connector used, the cable harness can also be divided into connector-type cable harness and terminal-type cable harness. Connector-type cable harnesses are typically equipped with standardised connectors for quick plug-in and replacement for applications requiring frequent connections and disconnections; terminal-type cable harnesses are connected directly through terminals, and more stable electrical connections are available for fixed installations.

For cable and wire harnesses’ disadvantages, you will meet many problems such as the mission of transmitting the electrical signal or power. Your products will be exposed to moisture, chemicals, salt and more other things. The second problem is corrosion weakens as the reason for the corroded electric contact, the resistance increased. Then you can’t find the signal. What’s more, it’s a revolving reaction. If your product is moist, it will increase the risk of joint failure.

For the second problem, which is a connector failure, it may be loose, it may be damaged, or affect the function or short circuits as the reason for inserting or unplugging too much. Or, if you use them in a vibrating surrounding. It’s also resulting in equipment failure or security risks.

For the third problem, which is overweight, especially in aerospace, automotive and other weight-sensitive applications, excessive wiring harness will increase the weight of the entire system, affecting performance and fuel efficiency. Therefore, materials and structures need to be considered in the design and selection of wiring harnesses to ensure that they meet functional requirements and are as light as possible.

In a word, cable harness may face corrosion, joint failure, overweight and other problems in the course of use. In order to ensure the reliability and long life of the wiring harness, appropriate protective measures, such as use of corrosion-resistant materials, regular inspection and maintenance of connectors, and optimization of wiring harness design to reduce weight.

If you say the quantity in a plane, it can be up to 400 wires in most ones. Let alone the large-scale automobiles, industries and home appliances. Then, the cable harness needs to transmit signals and the number of power will affect the number of wires. What’s more, If you have a complex system, it may require more wires to transmit data, control signals, and power.

The type and number of connectors used also affect the number of wires in the harness, as multi-pin connectors usually require more wires. Also, some applications may require additional shielding or protection wires to prevent electromagnetic interference or mechanical damage.

In a word, if it’s a simple harness, it has only a few wires at least. Nevertheless, if it is a complex harness, it contains hundreds of wires. Due to satisfy the needs of a variety of sensors, control modules and electrical equipment.

Battery cable harness is a harness system designed to connect a Battery to other electrical components. It is commonly used in automobiles, ships, industrial equipment and other battery-powered equipment. The primary function of the battery cable harness is to ensure that the battery provides power to the device in a stable and safe manner.

This product is very safe, because it uses the wire usually is the thick specification copper wire or the aluminium wire, guarantees can bear the high current. Conductors are usually insulated to prevent short circuits and damage. It is equipped with specially designed connectors for connecting with battery terminals and other electrical components. These connectors need to have good electrical conductivity and mechanical strength to ensure reliable electrical connections. To increase durability and safety, protective bushings or bellows are also commonly provided to protect conductors from mechanical damage, chemical corrosion and environmental effects. Fuses or circuit breakers may be integrated into the battery cable harness to prevent overcurrent and short circuit. These protection devices can automatically disconnect the circuit, protect equipment and batteries when the current exceeds the safety limit. For ease of installation and maintenance, battery cable harnesses are usually labelled and labelled to indicate the function and connection location of the wires.

Battery cable harness design and manufacturing process need to consider a variety of factors, including current load, environmental conditions, mechanical stress and safety requirements. The high-quality battery cable harness can ensure stable and reliable power transmission between the battery and the equipment, and extend the service life of the equipment.

An engine harness is a group of wires and related components, it used to connect the various electronic components of an engine. It plays an important role in various equipment such as automobiles, Electric tools, home appliances and so on. Especially in automobile engines, the wiring harness’s function is particularly important.

It is also safe, as it consists of several conductive copper wires, and, it is encased in insulation to prevent short circuits and electric shocks. What’s more, the wire harness is sheathed and protected, usually made of plastic or rubber, to protect the wire from wear, heat and chemicals. They are also secured to the engine and body with corresponding clips and straps to prevent them from being moved or damaged in the course of the vehicle.

It not only transmits power from the battery and generator to the various electrical components of the engine, such as the ignition system and the Fuel injection. Can also transmit signals, transmission of data from various sensors to the engine control module for real-time monitoring and adjustment. More control signals, and transmission control signals, so that the engine control module can control a variety of actuators, such as fuel injectors, ignition coil and so on.

Looking for Affordable Cable Harnesses for Your Project?

Home > Applications > LED Accessories

Home > Applications > LED Accessories

As a renowned cable harness solution provider giant VOCSON can ensure that your project is leading the industry, Choose us to provide wire harness products, and OEM or ODM services for you.