AWG Wire Size 101: How To Calcula, Measure, and Use?

Wire gauge is a standardized system across industries to measure wire’s diameter and cross-sectional area, which determines the wire’s carrying capacity and resistance. The larger the gauge number is, the smaller the wire diameter is, meaning the wire can conduct less electricity safely than wire with a smaller gauge.

AWG(American Wire Gauge) is the most common wire gauge system in North America. It mostly refers to solid and round wires that consist of a single strand. When it comes to multiple conductors in a wire, which is also called stranded wire, AWG denotes the equivalent single-strand gauge by combining the cross-sectional areas of all single strands.

In this blog, we will introduce ways to calculate AWG wire parameters, steps to measure the wire’s diameter, and common applications of different sizes, ensuring optimal and reliable performance of electrical systems.

How to calculate AWG wire size?

The next is precise ways to calculate wire’s diameter and cross-sectional area, and the way to get wire AWG through these two parameter.

To get the wire’s diameter:

Way 1: Measure the single solid wire’s diameter using a caliper or gauge tool. (Not include the size of insulation)

Way 2: AWG formula for solid wire

d = 0.005inch * 92^((36 – n)/39) = 0.127mm *92^((36 – n)/39)

d = diameter of single wire

n = AWG gauge number

There are 40 gauge numbers in the AWG system, from 0000 (4/0) to 40 AWG. 36 AWG is 0.005 inches in diameter. The largest wire is 0000 AWG(0.46 inches/11.68 mm), and the smallest wire is 40 AWG(0.0031 inches /0.079 mm).

No measures to directly measure the diameter of stranded wire for the gauge represent the equivalent solid wire diameter.

To get the wire’s cross-sectional area:

AWG formula for cross-sectional area:

A = π * (d/2)²*N

A: cross-sectional area

d: diameter of single strand

π: 3.14

N: Number of conductor strand

If it is a solid wire, “N” represents 1, and “d” is the diameter of the wire. If it is a stranded wire, “N” represents the strand number, and “d” should be the diameter of a single strand.

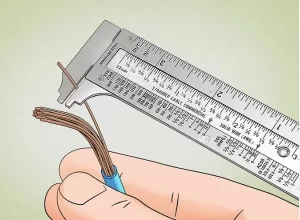

To get AWG:

Get the diameter and cross-sectional area and correspond to the AWG table to get AWG:

(“20 AWG,0.518, 10/0.26”, this respectively refers to AWG size, cross-sectional area, strand number, and single strand’s diameter.)

For example:

If you measure wires with a diameter of 0.0641 inches, the cross-sectional area should be 0.00323in²or 2.08mm². The closest AWG size is 10 AWG.

Steps to measure AWG wire diameter

As we can see, as long as we get the diameter of the wire, we can easily know the cross-sectional area and wire AWG. So, in this part, we will lead you to practice stripping the insulation and calculating the diameter of solid and stranded wire.

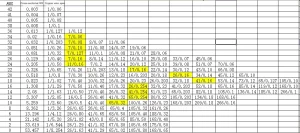

Strip the wire insulation

The diameter of the conductor doesn’t include the protective coating, so we have to strip the insulation first.

Insert a 2-inch length of wire through the stripper which should fit snugly into the small and pointed hole. Clamp and pull off the insulation with about 2 inches(5cm) of wire exposed.

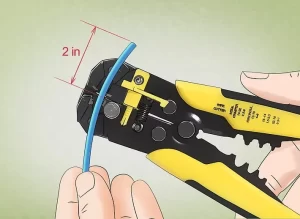

Measuring the diameter of circular solid wires

Measure a single or solid wire diameter with the gauge tool. Each hole on the gauge tool corresponds to a different gauge size.

Estimate the size of the wire and slide the wire into the gauge groove to see whether it fits, and ensure the wire has a better fit to the size of the smallest gauge slot it slides into. The gauge size on the tool is just the AWG size of the wire.

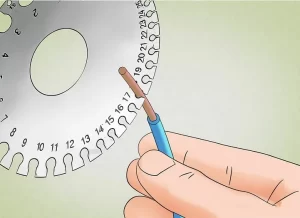

Measuring the diameter of stranded wires

As we have mentioned, we need to measure the single strand’s diameter for stranded wires. Here, we should use the caliper, and if the gauge is very large(very small diameter of single strand), we should make use of a micrometer caliper or conduit measuring device.

Applications of different-sized AWG wires

Reasonable application of AWG wires is essential for safety and maintenance. Wrong wire gauge utilization will cause potential risks. For example, if we use too small a wire(high AWG), the wire is hard to undertake high electricity with a small current carrying capacity, then, the wire may overheat, melt, or catch fire.

Next is a breakdown of the common applications of different-sized AWG wires in our daily lives:

Very small wires:

- 40AWG is used for microelectronics and specialty devices, such as RFID tags or miniature sensors.

- 30AWG is used for precision electronics and sensors, such as microcontrollers and medical devices.

Small wires:

- 24AWG is used for electronics and small devices, such as USB cables and phone chargers.

- 20AWG is used for signal cabling and low-current systems, such as speaker wires and sensor connections.

- 18AWG is used for low-voltage lighting,lamp cords, and electronics at 10 amps, such as doorbells.

Medium wires:

- 16AWG is used for light-duty extension cords supporting 13 amps.

- 14AWG is used for lighting and general-purpose circuits, such as light fixtures, lamps, and small appliances with 15 amps.

- 12AWG is used in standard household circuits, such as kitchen, bathroom, outdoor receptacles, and 120-volt air conditioners supporting 20 amps.

- 10AWG is used inhousehold appliances and circuits, such as electric clothes dryers, 240-volt window air conditioners, and electric water heaters supporting 30 amps.

Large wires

- 6AWG is used forhigh-power circuits, such as cooktops and ranges carrying 40-50 amps.

- 4AWG is used for electric furnaces and large electric heaters protected at 60 amps.

- 1AWG is used for heavy-duty wiring, such as electric ovens and dryers.

- 0000(4/0)AWG is used for power distribution, such as industrial facilities and large buildings.

Where to buy high-quality wires?

When it comes to high-quality wires, I recommend Vocson who has stuck to manufacture wires, and cable harnesses for years. Taking quality and custom at first, Vocson is committed to doing well on each project and meeting your multi-layer needs, welcome to contact us and learn more details about our wire and cable tech.

Related Reading

Types and Applications of Copper Wire: A Step-by-Step Guide

Tinned Copper Wire VS Bare Copper Wire: Definition, Benefits, Applications, and How to Choose

Different Types of Electric Wires: Residential Application, Uses and How to Select

Comprehensive Electronic Wires Selection Guide (8 Key Points)